Ultrasonic Machining Is Best Suited for Which Material

It is best suited for machining hard and brittle materials. The advantages of ultrasonic machining are.

Ultrasonic Machining Parts Working Applications Advantages And Disadvantages

Hard and ductile Most commonly used flame in gas welding is Neutral.

. Call our Experts Today. For cutting glass and ceramics alumina is found as the best. The following Ultrasonic Machining applications are.

USM process is used in machining hard and brittle metallic alloys semiconductors glass ceramics carbides etc. The ultrasonic machining is best suited for tool steels sintered carbides glass plastics etc. Ultrasonic Machining is used for the Machining of non-conductive ceramics.

1 Best suited material so far is Medium Togh steel which offers best compromise between cutting rate and tool wear 2 Material used for Ultrasonic machining Tool must be ductile and strong as it has to hit abrasive slurry as many times as the workpi. None In case of a shaper the feeding of the job is done At the beginning of the cutting stroke. Material that has a high scrap rate means fragile material can be machined by this process very effectively.

This process is. This process is best suited for brittles materials. USM is suited for hard materials hardened steels and brittle materials ceramics carbides glass and precious stones.

The abrasive particles as they indent the work material would remove the work material particularly if the work material is brittle due to crack initiation propagation and brittle fracture of the material. See the answer See the answer See the. 03 Explain why ultrasonic machining is best suited for hard and brittle materials.

This process is used for drilling both spherical and non-spherical holes in very hard materials like carbides ceramics. Best suited to poorly conducting materials and brittle materials. The carbide tools operating at very.

The machining operation is simple takes less time. Whether a workpiece is made of glass ceramic or even quartz its physical dimensions can be altered using ultrasonic machining. Boron is the most expensive abrasive material and is best suited to the cutting of tungsten carbide tool steel and gems.

This method is the best choice for working with hard materials such as ceramic matrix composites ruby piezo-ceramics glass ceramics Quartz ferrite diamonds technical ceramics alumina PCD sapphire CVD silicon carbide and similar ones. Ultrasonic machine is best suited for A. Image Not Yet Uploaded.

15 to 60 mmin. Thickness gauges flaw detectors bolt monitors and accessories. The machining operation is simple and requires less time.

Ultrasonic machining is best suited for. Consider the following workpiece materials i. It produces good surface finish.

It cuts materials at very slow speeds. This process is best suited for brittle materials. The advantages of Ultrasonic Machining are.

Any one of these. Machining of dies for wire drawing punching and blanking operations. 60 to 90 mmin.

This process is used for drilling both circular and non-circular holes in very hard materials like carbide ceramics. Comment Related Questions on Manufacturing and Production Technology. This type of machining may be used for machining of hard and brittle materials.

03 Explain why ultrasonic machining is best suited for hard and brittle materials. This problem has been solved. Ultrasonic machining cuts materials at very slow speeds and produces good surface finish.

The tool present in the machine for cutting the materials is made from a soft material as compared. Aluminum oxide alumina boron carbide silicon carbide and diamond dust. Ad High-Quality Industrial Ultrasonic Testing Equipment.

Ultrasonic machine is best suited for. I hope you enjoying and flowing with words. The abrasive slurry used in ultra-sonic machining contains fine particles of.

Originally used for finishing EDM surfaces. Which of the following statement is wrong about ultrasonic machining. Ultrasonic machine used for removing metal from hard materials like- Diamond boron carbide Quartz tempered steel ruby ceramics glass alumina saphhire.

90 to 120 mmin. The basic process is a ductile and tough tool is pushed against the work with a constant force. Ultrasonic machining is unique however because its capable of removing material from nearly all types of workpieces including those made of hard and brittle materials.

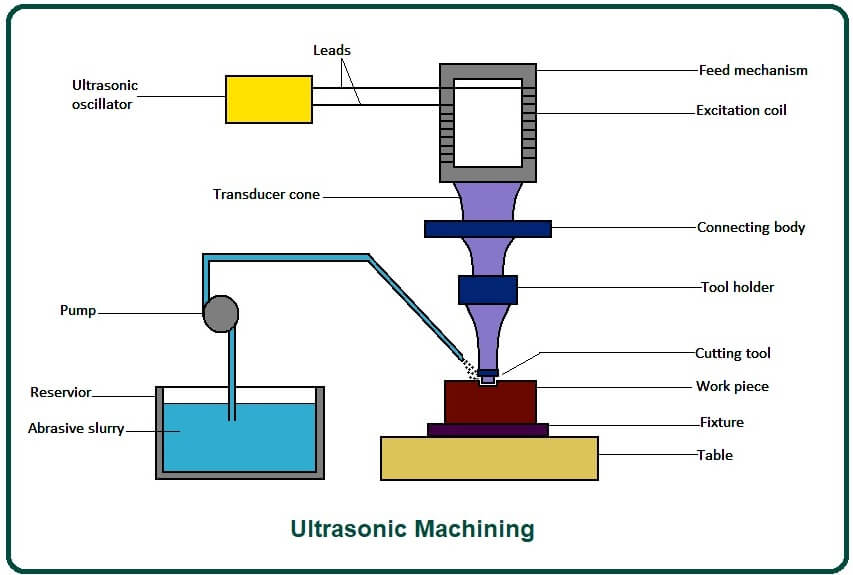

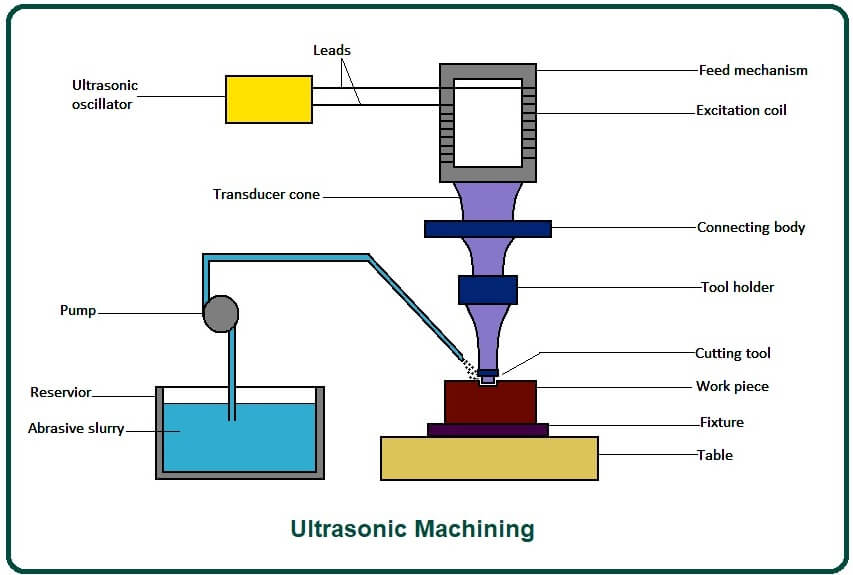

For what type of materials ultrasonic machining USM is most suited. Silicon finds the most application. Ultrasonic Machining USM First built 1950s.

The reasons which are basically responsible for the formation of a queue should be that. Explain why parts with irregular shapes sharp corners deep recesses and sharp projections can be difficult to polish. A hole is to be drilled in 20 mm thick tungsten carbide sheet by.

At the middle of cutting stroke. Ceramics Materials best suited for ultrasonic machining are. It was stated that ultrasonic machining is best suited for hard and brittle materials.

It removes large amount of material. The ultrasonic machining is best suited for material that is Soft and ductile.

What Is Ultrasonic Machining Working Principle Of Ultrasonic Machining Parts Of Ultrasonic Machining

Comments

Post a Comment